Case studies

Recology

For Recology, US HydroTech has installed two BIO Enzyme Water Recycle Systems on two sites in order to eliminate oils/grease and odor, manage pH and recycle/discharge wash water to the sanitary sewer. The same system serves two different applications washing trucks and washing waste bins.

The BIO Enzyme System utilizes fixed-film bacteria in conjunction with coalescing media. Various tank sizes and flow rates are used to create retention time for the treatment of wastewater streams. Oxygen is supplied to the bacteria in the waste stream by venturi injection.

Recology started with one system at a site where they washed their waste collection trucks. They had excellent results with the system. Because the BIO Enzyme Water Recycle System is both low maintenance and versatile, after a few years, they installed another identical system at a second site, which they use for washing waste bins.

BIO Enzyme System Features

- Lowest maintenance recycle system on the market

- CSA-approved control panel

- Simple equipment operation

- Versatile to multiple water recycling applications

BIO Enzyme System Component Details

Submersible Sump Pump: Untreated water is introduced into the BIO system via a 1/2 HP submersible sump pump.

Waterfall Filter (optional): Especially useful in golf course applications, water is typically pumped to a stainless steel waterfall filter for effective grass and particle separation. Water flows into the system while grass and debris are separated and dropped into the grass cart.

Grass Cart (optional): Grass from the waterfall filter is collected in the grass cart. Grass is de-watered through a specially designed stainless steel screen in the grass cart that allows the cart to be filled with grass and debris without plugging up the screen. Water drains back to the pit, and the grass can be easily transported for disposal.

Bioreaction Tank: Untreated wastewater is pumped into the first chamber of the stainless steel tank, where solids are precipitated and the microbes begin their work. The tank has up to 2,244 gallons of holding capacity to provide maximum treatment time for the biological microbes.

Biofilm Generative Media: The bioreaction portion of the system houses literally thousands of square feet of biological media surface area, where the microbe growth is maximized. Water flows through the media and around a series of baffles, changing direction countless times, and maximizing contact with “hungry” microbes. The microbes then treat the water by consuming a broad range of organic constituents (such as herbicides, pesticides, oils, greases, etc.), turning them into carbon dioxide and water. To ensure proper and continued colonization, microbes are added periodically through a process called inoculation.

Aeration System: A unique aeration system quietly injects large amounts of oxygen into the wastewater. Generating dissolved oxygen is critical for maximizing the health and activity level of the microbes and the size of the colony.

Ozone (optional): An ozone generator is an option for specialized applications where sterilization of the waste stream is desired. (Please note that ozone injection is not available for aluminum tank systems.)

Pressurized Tank: Once water is biologically treated, a pressurized tank and pump deliver up to 35 GPM of recycled water to three outlet ports.

Peristaltic Pump (optional): Self priming for passive automatic liquid microbe injection.

Sloped Bottom Tanks (optional): Makes regular scheduled maintenance easier.

CONTACT US

TALK WITH AN EXPERT

We have a cost-effective and environmentally friendly solution for operations of all shapes and sizes in the United States.

Contact Us – Sidebar

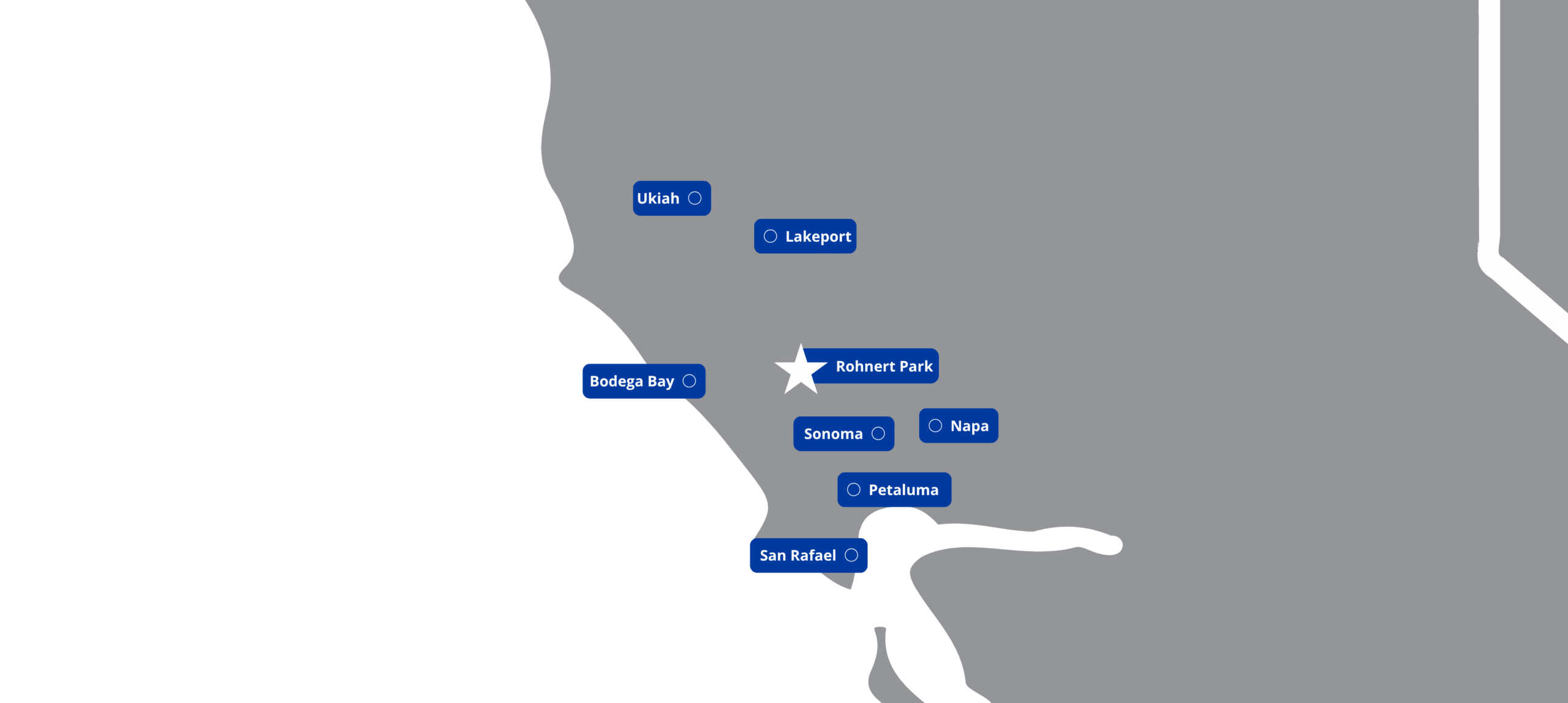

CONVENIENT LOCATIONS

Servicing THE NORTHERN BAY AREA

We provide quality service and repair for your industrial pressure cleaning equipment in the Sonoma County, California area. We offer in-store or on-site (within 40 miles) servicing and preventative maintenance.